PRODUCT

- PU foaming machine

- Pentane foaming machine

- PU spraying machine

- PU storing system

- PU pre-mix system

- Chemical measuring device

- PU sweeping material device

- PU products and molds

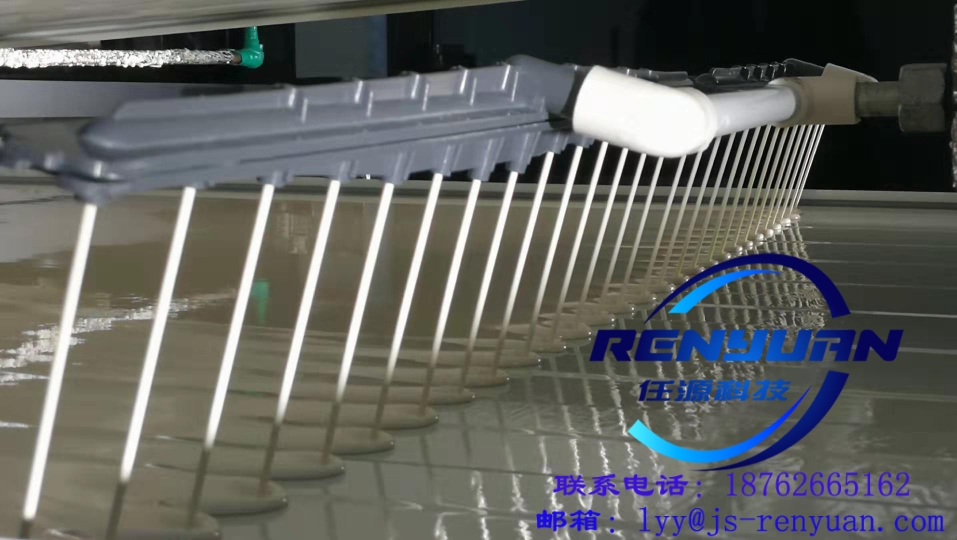

spraying bar for PU sandwich panel production

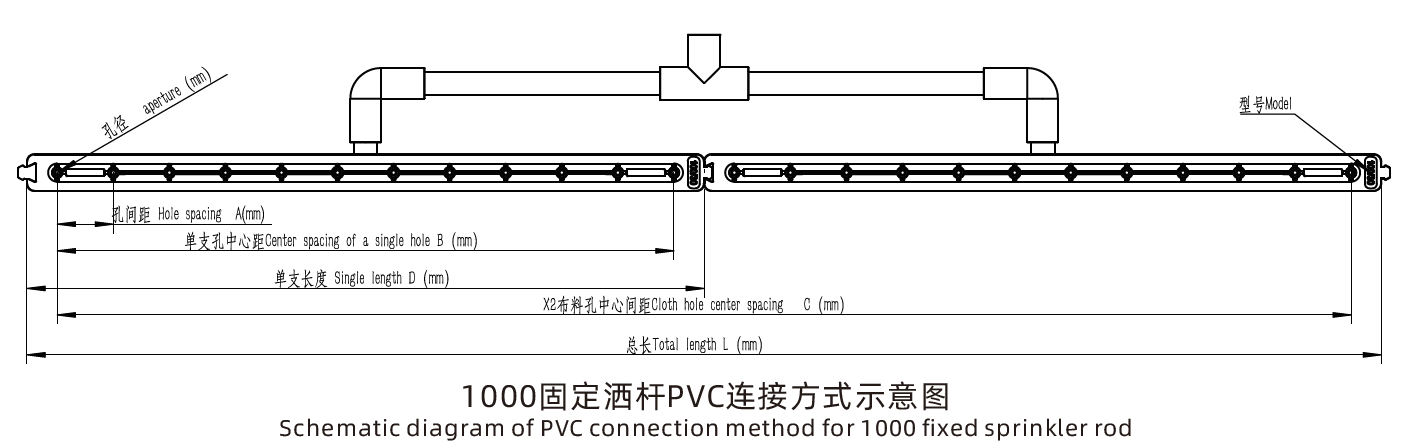

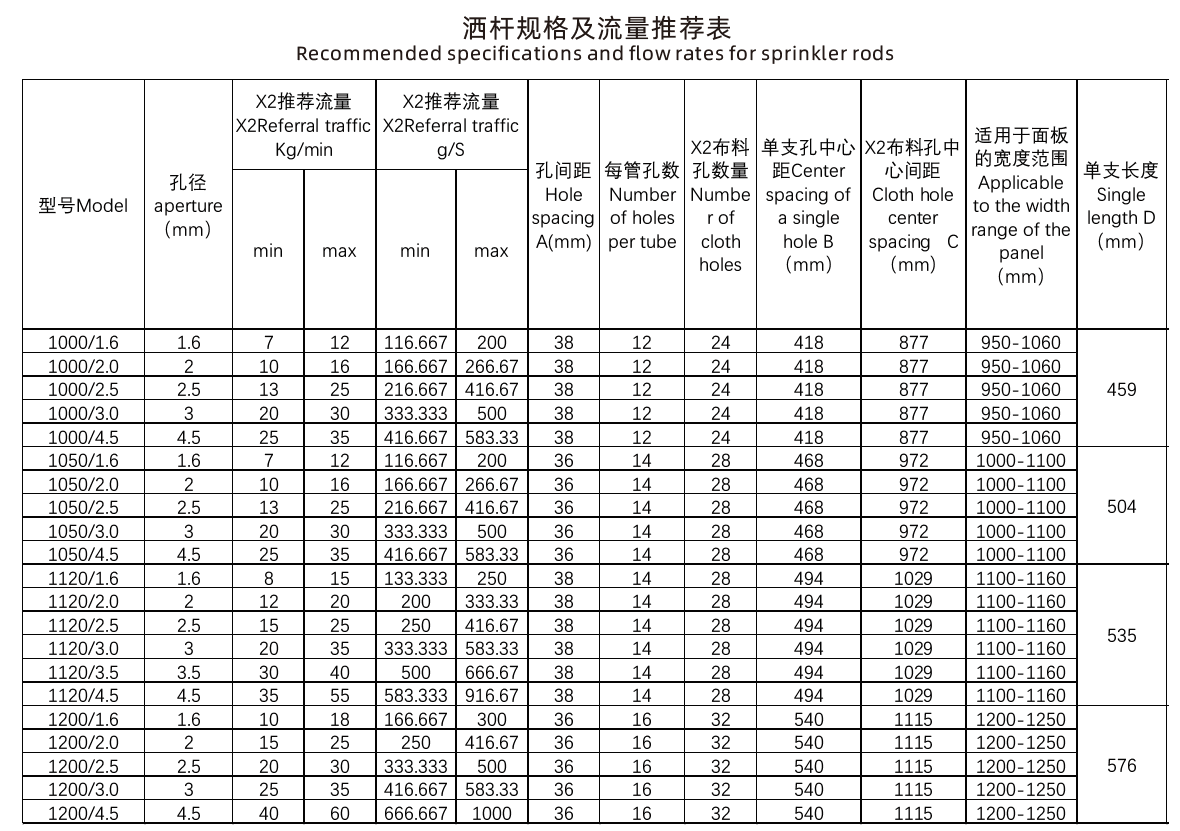

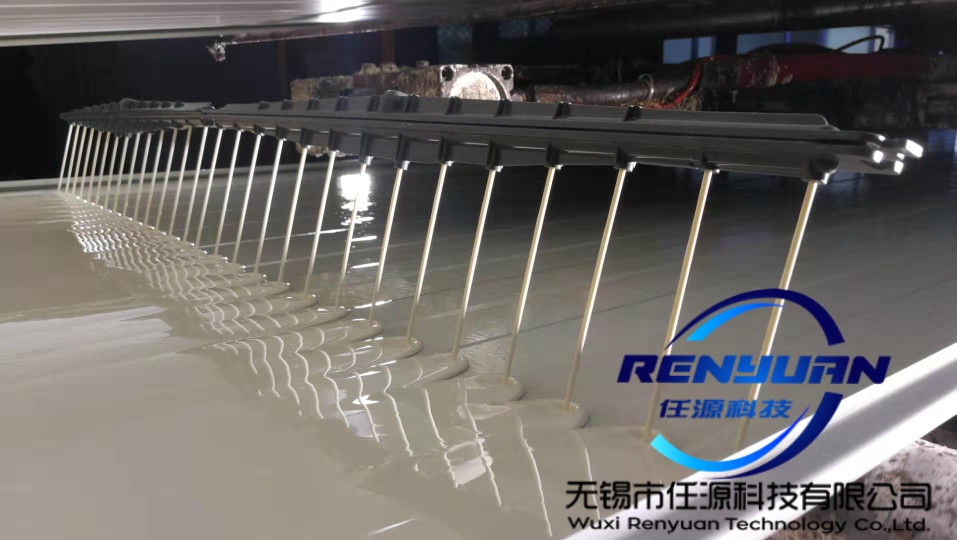

In the production process of PU sandwich panel, the material spraying is very key, which directly affects the quality of PU sandwich panel.At present, the method of reciprocating sweeping pouring is generally adopted, the surface material moves forward continuously at a certain speed, and the reciprocating sweeping pouring head continuously sprinkles the PU material on the surface material. Its disadvantage is that the PU material pours on both sides repeatedly and wastefully. It is easy to mix a lot of bubbles during pouring. There are some defects in the product, such as bubble, different density distribution of core material and insufficient filling due to uneven pouring. According to years’ production experience and repeated adjustment of production process, this spraying bar is developed by adopting fixed pouring method. By improving the defects of traditional foam spraying, the quality of sandwich panel can also be greatly improved.

- Previous article:No more

- Next article:No more